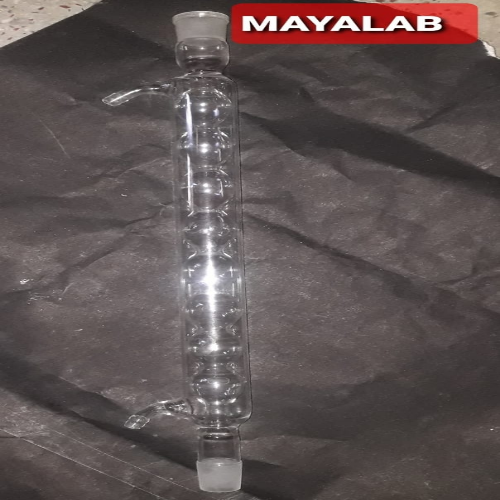

Glass condenser

650.0 INR/Piece

Product Details:

- Glass Type borosilicate

- Display Type MANUAL

- Temperature Resistance yes

- Shape tube

- Usage distillation

- Type Condensers

- Size 300mm

- Click to View more

X

Glass condenser Price And Quantity

- 10 Piece

- 650.0 INR/Piece

Glass condenser Product Specifications

- borosilicate

- 300mm

- glass

- transperent

- borosilicate

- borosilicate glass condenser

- MANUAL

- yes

- distillation

- Condensers

- distillation parts

- tube

Glass condenser Trade Information

- DELHI

- Cash Advance (CA), Cash in Advance (CID), Telegraphic Transfer (T/T)

- 2000 Piece Per Month

- 2 Days

- Sample costs shipping and taxes has to be paid by the buyer

- box

- All India

- iso

Product Description

The condenser cools these vapors condensing them back to liquid droplets that flow down the condenser into the receiver flask. A completely filled condenser provides maximum cooling therefore allowing for maximum recovery of the purified liquid during distillation.The condenser cools these vapors condensing them back to liquid droplets that flow down the condenser into the receiver flask. A completely filled condenser provides maximum cooling therefore allowing for maximum recovery of the purified liquid during distillation.FThe condenser cools these vapors condensing them back to liquid droplets that flow down the condenser into the receiver flask. A completely filled condenser provides maximum cooling therefore allowing for maximum recovery of the purified liquid during distillation.The condenser cools these vapors condensing them back to liquid droplets that flow down the condenser into the receiver flask. A completely filled condenser provides maximum cooling therefore allowing for maximum recovery of the purified liquid during distillation.The condenser cools these vapors condensing them back to liquid droplets that flow down the condenser into the receiver flask. A completely filled condenser provides maximum cooling therefore allowing for maximum recovery of the purified liquid during distillation.The condenser cools these vapors condensing them back to liquid droplets that flow down the condenser into the receiver flask. A completely filled condenser provides maximum cooling therefore allowing for maximum recovery of the purified liquid during distillation.The condenser cools these vapors condensing them back to liquid droplets that flow down the condenser into the receiver flask. A completely filled condenser provides maximum cooling therefore allowing for maximum recovery of the purified liquid during distillation.

Efficient and Reliable Distillation

Engineered from premium borosilicate glass, this condenser ensures robust thermal resistance and clear visibility throughout your distillation processes. Its 300mm tubular structure enhances cooling efficiency, making it a dependable choice for precise laboratory and industrial applications. Transparent design aids in easy monitoring and troubleshooting during outcomes.

Versatile Applications Across Industries

Whether you are in research, manufacturing, or academics, this condenser is designed to suit your distillation needs. The products adaptability spans laboratories, chemical plants, and educational settings, providing consistent results in varied applications. Its compatibility with manual display systems simplifies operation and integration with other equipment types.

FAQs of Glass condenser:

Q: How is the glass condenser used in distillation processes?

A: The glass condenser facilitates the cooling and condensation of vapors during distillation. As vapor passes through the transparent borosilicate tube, it cools against the outer surface and converts back to liquid, which can then be collected.Q: What makes borosilicate glass an ideal material for this condenser?

A: Borosilicate glass offers excellent resistance to thermal shock, chemical corrosion, and mechanical stress. These properties ensure longer durability and consistent performance in high-temperature laboratory and industrial distillation tasks.Q: When should I choose a 300mm glass condenser for my setup?

A: A 300mm condenser is suitable when your distillation process requires moderate to high cooling capacity, which is common in mixing, purification, or analytical distillations in laboratories or production facilities.Q: Where can I purchase or source this glass condenser in India?

A: The condensers are available through various channels such as manufacturers, suppliers, wholesalers, dealers, and exporters across India. You can contact local distributors, lab equipment suppliers, or reach out to service providers listed online.Q: What is the benefit of a transparent tube-shaped condenser?

A: The transparent tube design allows users to closely monitor vapor condensation and flow during operation, making maintenance, troubleshooting, and quality control much easier compared to opaque models.Q: How do I maintain the glass condenser for optimal performance?

A: Routine cleaning using appropriate solvents without abrasive materials is recommended. Inspect the condenser for cracks or wear before every use to ensure safety and efficiency during distillation processes.Q: What processes can this glass condenser be used for?

A: It is primarily designed for distillation but can also be employed in other condensation processes like reflux, extraction, and purification, thanks to its durable glass construction and temperature resistance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'glass condenser' category

|

MAYALAB INSTRUMENT

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |